Our hot melt glue machine has three

switches: the main power switch, the leakage switch in the electrical box, and

the key switch on the control panel. Turn on the three switches in sequence,

and the touch screen displays the boot up. Wait about 2 seconds to enter the

initialization interface. At this time, there are two different languages to

choose from, Chinese and English, and the control interface is displayed in

different languages to meet the operating needs of foreign friends. Here we

choose Chinese to enter the system, after entering the main interface, click

the gear button in the upper right corner to enter the temperature setting.

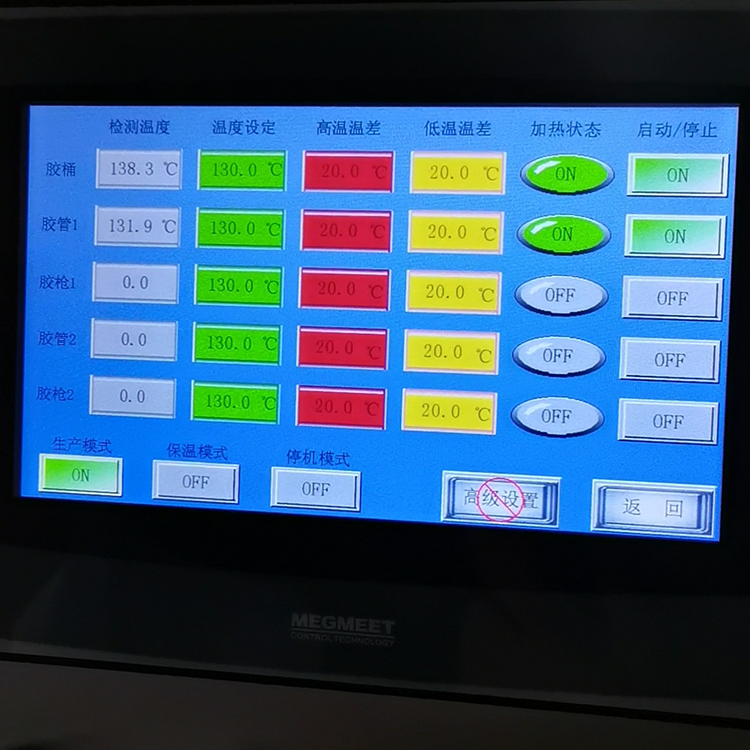

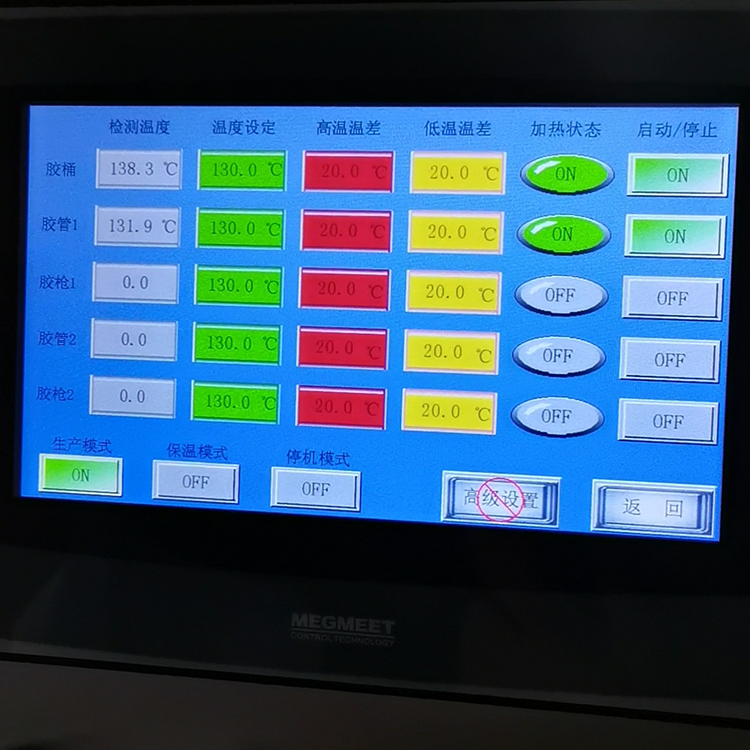

Our hot melt glue machine has 2 channels of

glue delivery and 5 channels, which are glue barrel, hose 1, glue gun 1, hose

2, glue gun 2. That is to say, you can connect up to two sets of hoses and glue

guns. Customers can Connect one or two sets of hose glue guns according to your

needs. We first click on the "temperature setting" of the uppermost

glue bucket, and the setting interface will automatically pop up. The working

temperature of PUR hot melt adhesive is lower than that of EVA hot melt

adhesive, usually at 120-140°C. Here we set it to 130°C, click OK. There is

"detection temperature" in front, it is the current actual temperature

of the rubber barrel detected by the system temperature sensor, we don't care

about it.

Then there are high temperature difference

and low temperature difference behind, this is only 20℃ by default,

which means that when the detected temperature is higher than the set

temperature and exceeds the high temperature difference, it will automatically

alarm, and it will not work if it is lower than the low temperature difference.

There is "Start/Stop" at the end. If we need to heat this part, set

the state to ON, otherwise, set it to OFF. Now we see that there is another

"heating state" that is OFF. This requires us to light up the

"production mode" in the lower left corner and it will automatically

change to the ON state before the heating mode is officially started. Next, we

will set the temperature of hose 1 and glue gun 1 in the same way. Here, hose 2

and glue gun 2 are temporarily unused, so we can set their

"start/stop" to OFF. After setting the temperature, click

"Production Mode" to start heating, and then click the Back button to

return to the main interface.

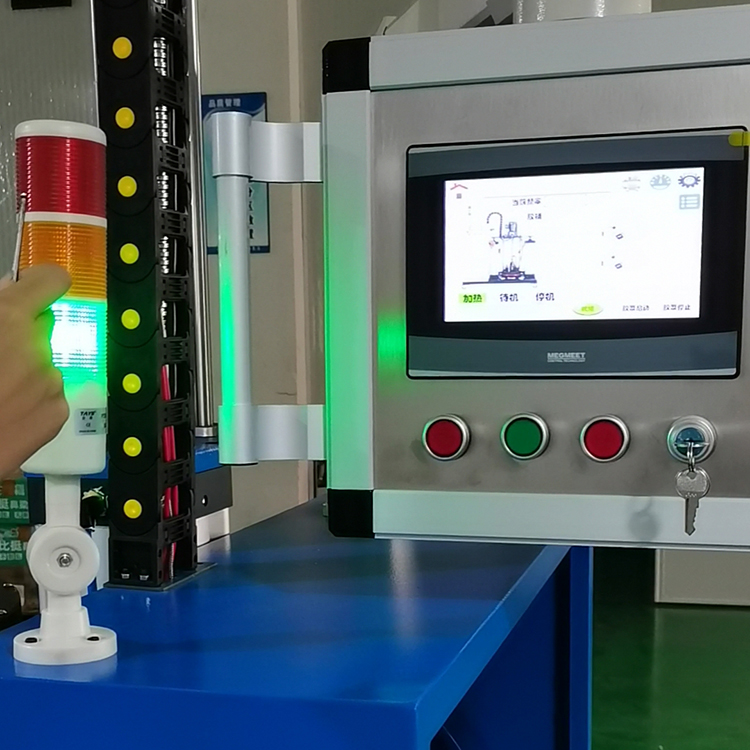

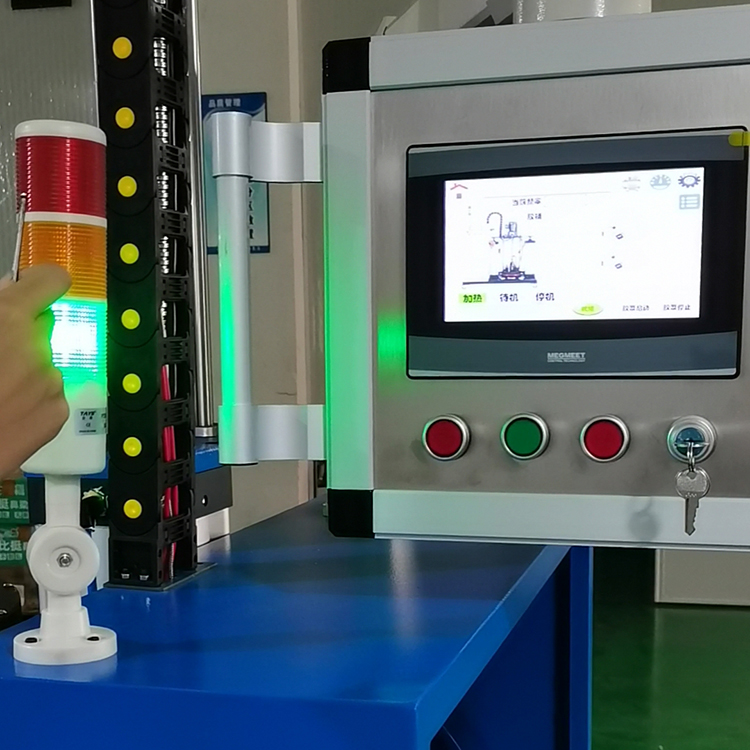

At this time, it takes 6-10 minutes to wait

for the hot melt glue machine to heat up. We can install the glue bucket first,

put the glue bucket on the bottom plate and position it properly. When the

three-color indicator light turns green, it indicates that the temperature has

reached the working state. We can press the "press down" button on

the control panel to slowly lower the pressure plate and approach the mouth of

the plastic bucket, check again whether the pressure plate is aligned with the

mouth of the plastic bucket, and lock the fixed block of the plastic bucket

after determining the position of the plastic bucket. . Then open the exhaust

valve and continue to press the seal ring of the pressure plate such as

"press down" into the rubber bucket and press the "automatic

press down" button. The platen will sense whether it touches the hot melt

glue and stop pressing. At this time, we pay attention When a small amount of

hot melt glue flows out from the exhaust valve, it means that the air in the

plastic bucket has been exhausted, and the exhaust valve can be closed.

After all preparations are completed, you

can click "Glue Pump Start" on the touch screen to start working.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик